Alumina ceramic is a ceramic material with alumina (Al₂O₃) as the main body.

High-purity alumina ceramics: Al₂O₃ content is above 99.9%, sintering temperature is up to 1650°C-1990°C, transmission wavelength is 1-6μm, light transmittance and alkali metal corrosion resistance, can be made into molten glass to replace platinum crucible, used as sodium lamp, can be used as integrated circuit substrate and high-frequency insulation material in the electronics industry.

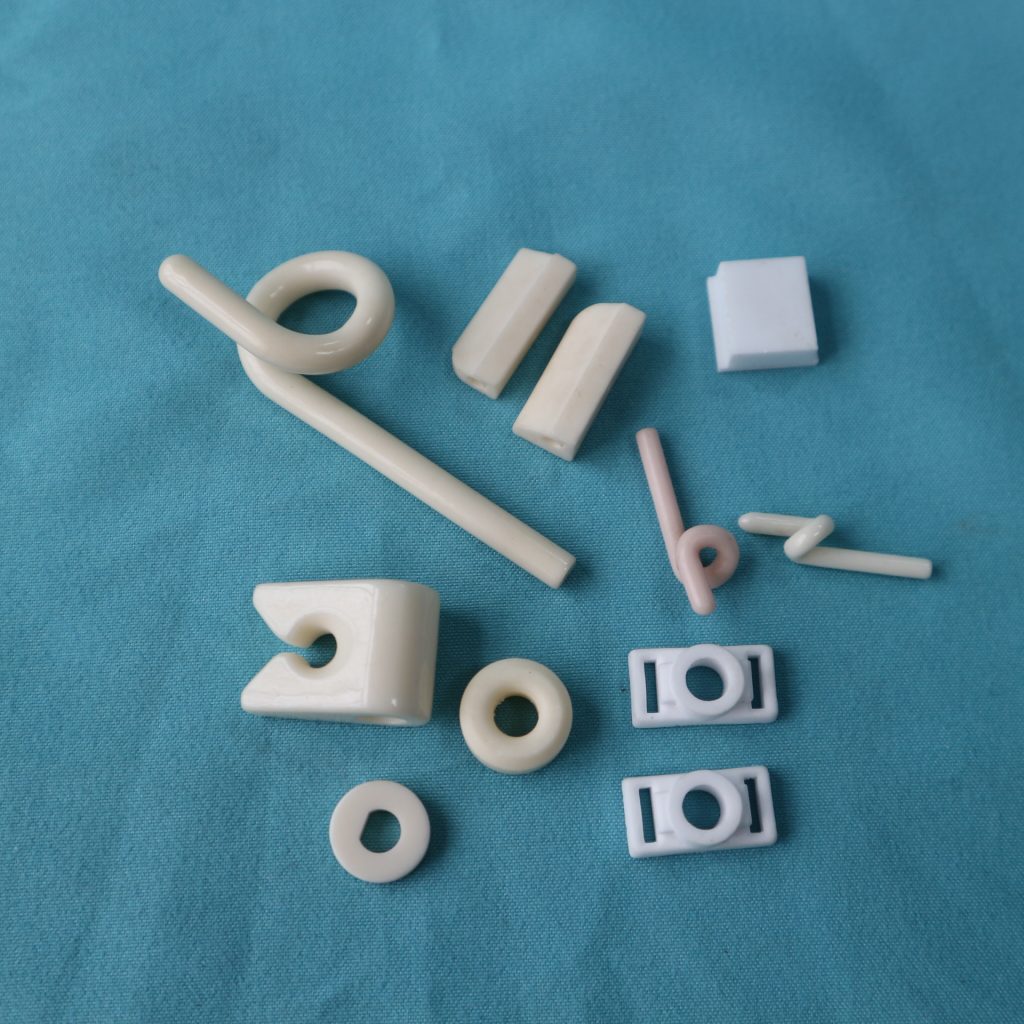

Ordinary alumina ceramics: according to the different Al₂O₃ content, it can be divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain and other varieties, and sometimes the Al₂O₃ content is 80% or 75% is also classified as ordinary alumina ceramic series. Among them, 99 alumina porcelain materials are used to make high-temperature crucibles, refractory furnace pipes and special wear-resistant materials; 95 Alumina porcelain is mainly used as corrosion-resistant and wear-resistant parts; 85 Because some talc is often mixed into porcelain, the electrical properties and mechanical strength are improved, and it can be sealed with molybdenum, niobium, tantalum and other metals, and some are used as electric vacuum devices.

Performance characteristics:

1)High hardness and abrasion resistance:

2)High strength and toughness: It has high compressive strength, fracture toughness and flexural strength, and can withstand large external forces and impacts.

3)Light weight: The density is about 3.5g/cm³, which is only half that of steel, which can reduce the load on the equipment and has advantages in applications where weight is required.

4)High temperature resistance: high melting point, can maintain stable performance in high temperature environment, can withstand high temperature of more than 1,000 degrees, suitable for the manufacture of high temperature parts such as high temperature stoves and spark plug insulators.

5)Good insulation: It still has good insulation properties at high temperatures, pure alumina porcelain can be used at a temperature of 800°C, and can be used to manufacture insulating parts such as electron tubes and rectifier shells and integrated circuit substrates.

6)Corrosion resistance: stable chemical properties, can resist most acid and alkali corrosion, can work stably in harsh chemical environments for a long time, such as used in the manufacture of chemical reactor lining, corrosion-resistant pipelines, etc.

7)Low coefficient of friction and self-lubrication: The surface is smooth, the coefficient of friction is small, and it has a certain degree of self-lubrication, which can be used to manufacture mechanical seals, bearings and other components that require low friction.